CAPEL Prototyping Service

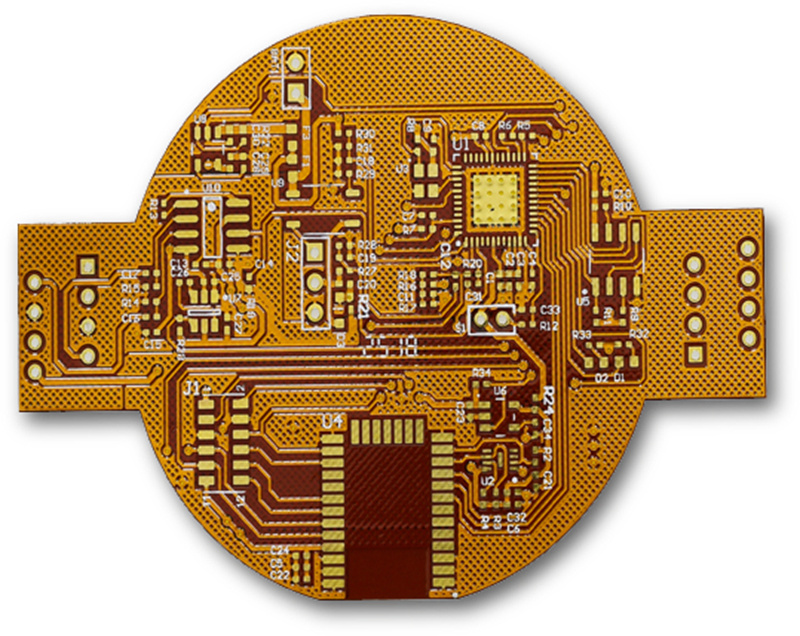

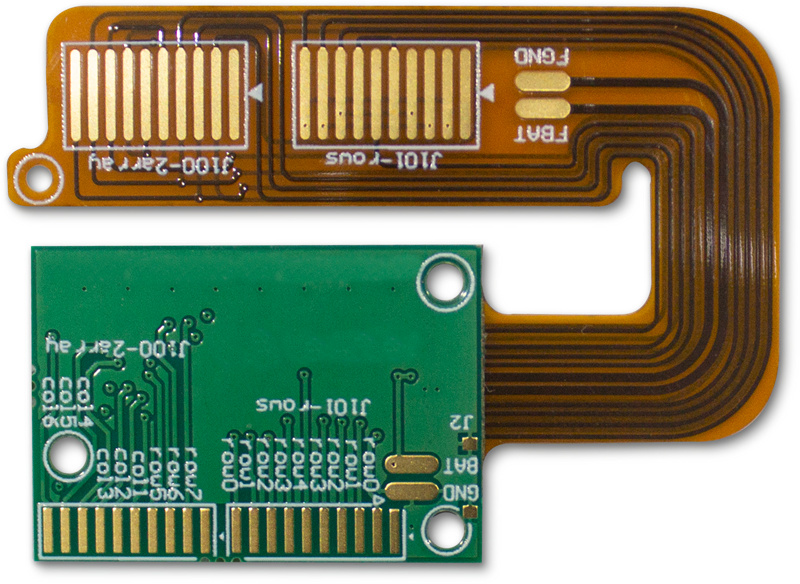

FPCs & PCBs & Rigid-Flex PCBs & SMT Assembly

Us produksjekapasiteit:

FPC en Rigid-Flex PCB's produksjekapasiteit kin mear as 150000sqm per moanne berikke,

PCB's produksjekapasiteit kin 80000sqm per moanne berikke, en assemblagekapasiteit op 150.000.000 komponinten per moanne.

Quick Turn Reliable PCB Prototyping

√ MOQ 1 stik

√ 24 oeren fluch beurt pcb prototype

√ 24x7 Online technyske ferkeaptsjinst

√ Gerber bestân evaluaasje foar produksje

√ Allround en snelle stipe foar logistyk tsjinst

√ Laser-boarre mikrovia's

√ fia-in-pad

√ Untwerp foar produksje (DFM) kontrôle

√ oant 60 lagen,

√ IPC Klasse 3 Standert

√ ymplemintaasje fan ISO 9001, ISO 14001, 5S en 6Q noarmen

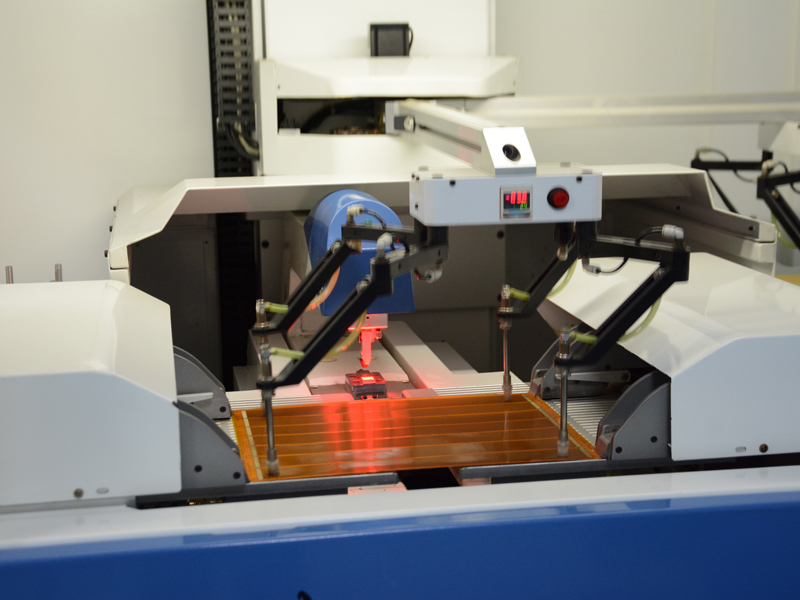

Kwaliteitsbeweitsing

√ IQC (ynkommende kwaliteitskontrôle)

√ IPQC(ln-proses Kwaliteitskontrôle)/FAl test

√ Visual Ynspeksje nei reflow oven / AOl

√ Fisuele ynspeksje foardat reflow oven

√ QA willekeurige ynspeksje

√ OQC (útgeande kwaliteitskontrôle)

√ High tech PCB Assembly tsjinst

(SMT/DIP line)

√ Sorcing fan profesjonele komponinten

√ Ynnovative programmearring en funksje test

PCB Assembly Service

√ SMT & PTH gearstalling

√ 1-2Days quick turn pcb assembly prototype

√ Snelle reaksje foar technyske stipe en advys

√ BOM-analyze om komponintuniformiteit en gegevensintegriteit te garandearjen

√ Troch Hole Board Assembly

√ Mixed Technology (SMT / Thru-hole)

√ Ien- as dûbelsidige pleatsing

√ Hege pin count parse fit steat Stive, fleksibele PCB en rigide flex PCB Assembly

CAPEL Underfining en sterkte

√ Manufacturing PCBs sûnt 2009

√ Sterk R&D Team mei 15 jier ûnderfining

√ Oanpast oant 60 lagen boards

√ Betsjinne gefallen belutsen by 100+ fjild

√ Kompleet bedriuwsysteem (eigen FPC / Rigid-Flex PCB-fabryk, PCB-fabryk, SMT-fabryk)

√ Folsleine ôfdielingsstruktuer

(R&D Department, Engineering Department, Overseas Sales Department, Purchasing Department, Production Department, Process Department, Quality Department, Warehouse Management Department, Logistics Management Department, Overseas After-sales Service Department)

√ Strikt en goed ferbettere kwaliteitskontrôlesysteem

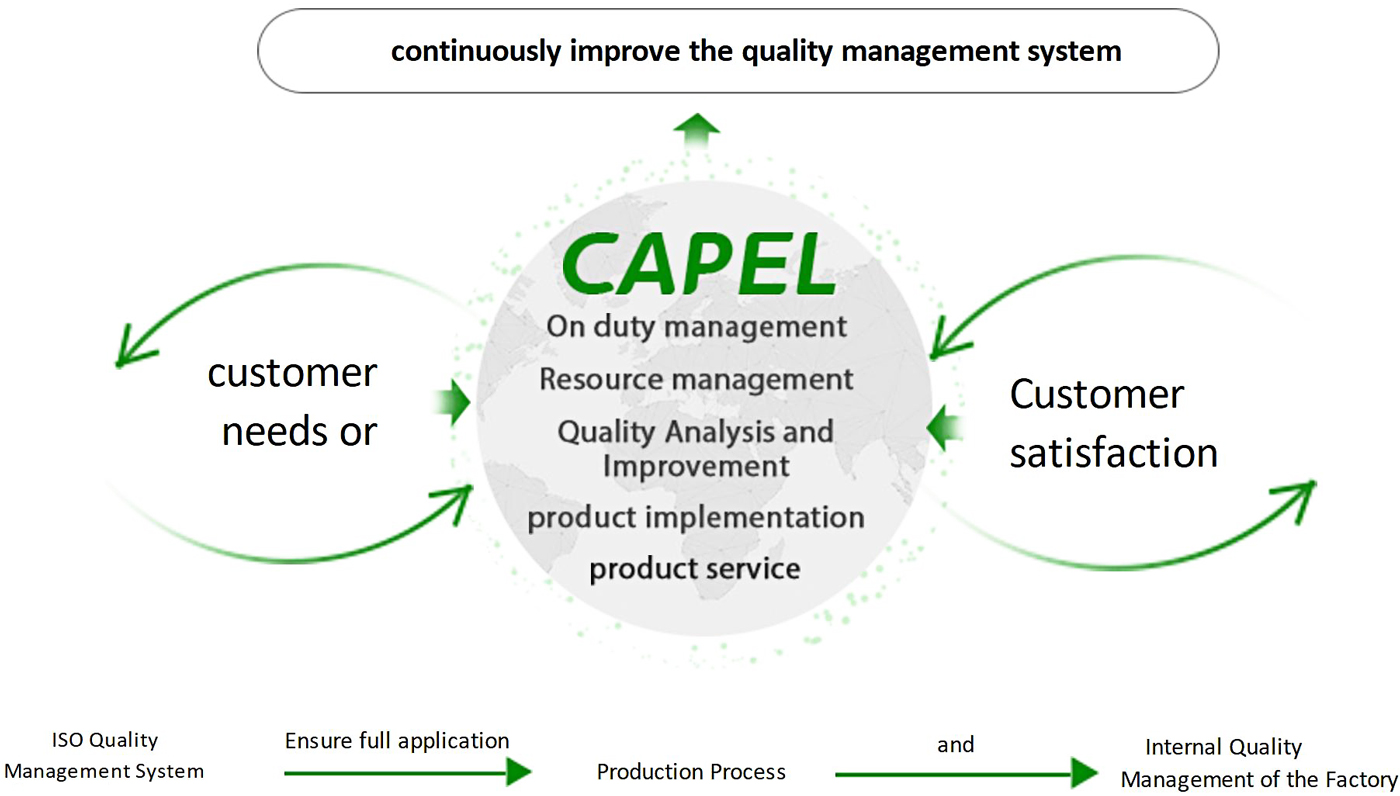

CAPEL's strikte kwaliteitskontrôlesysteem

Elk produkt produsearre troch it bedriuw moat strikte testen ûndergean om kwaliteit te garandearjen

CAPEL PCB Assembly Prototyping

Materiaalfoarrieding→ Solder Paste Printing→ SPI→ IPQC→ Surface Mount Technology→ Reflow Soldering

↓

Beskerming en ferpakking ← Nei welding ← Wave soldering ← Röntgen ←AOI ← Earste artide testen

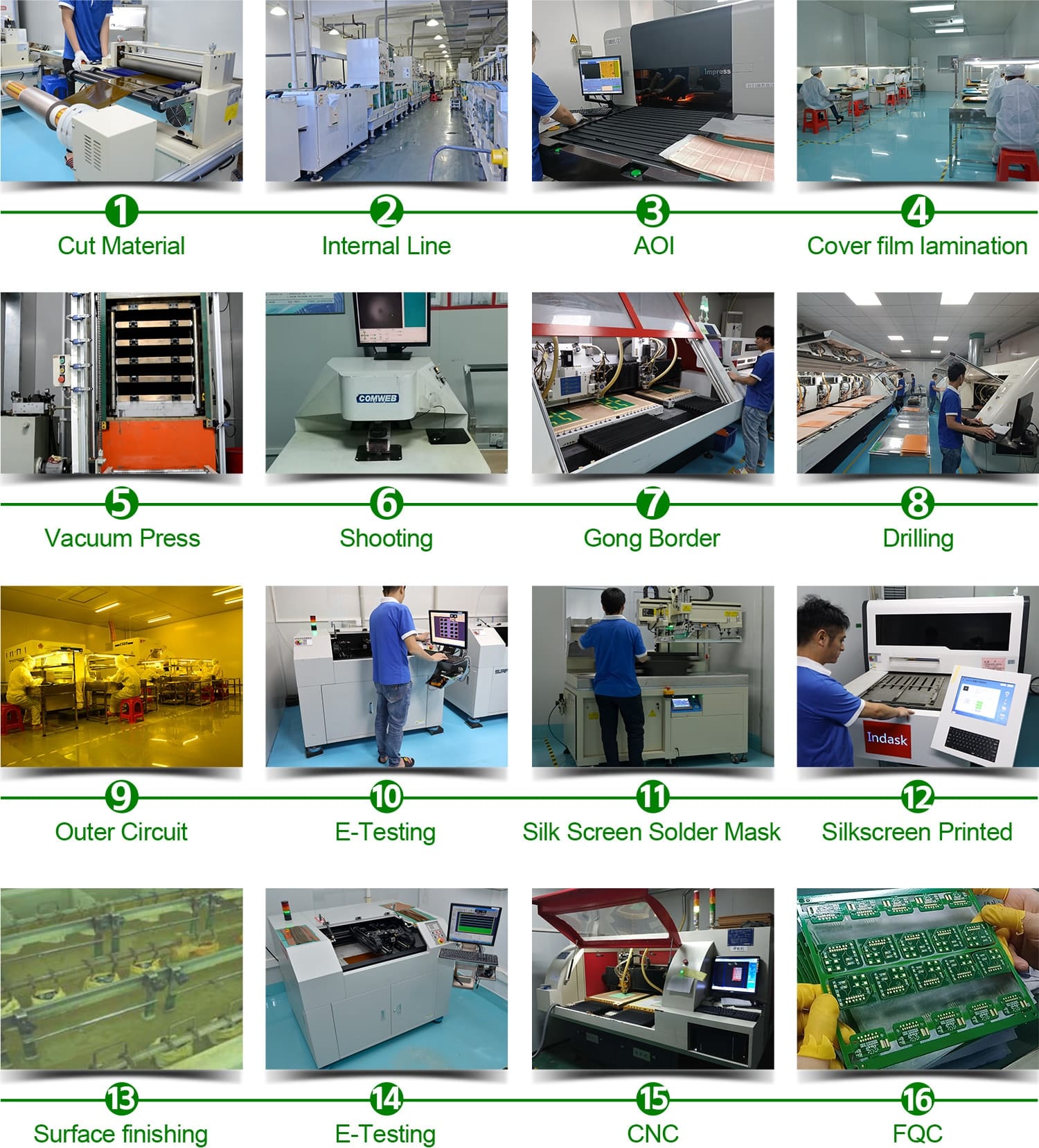

FPC produksjeproses

Shenzhen Capel Technology Co., Ltd.

Rigid-Flex PCBs produksjeproses

Shenzhen Capel Technology Co., Ltd.

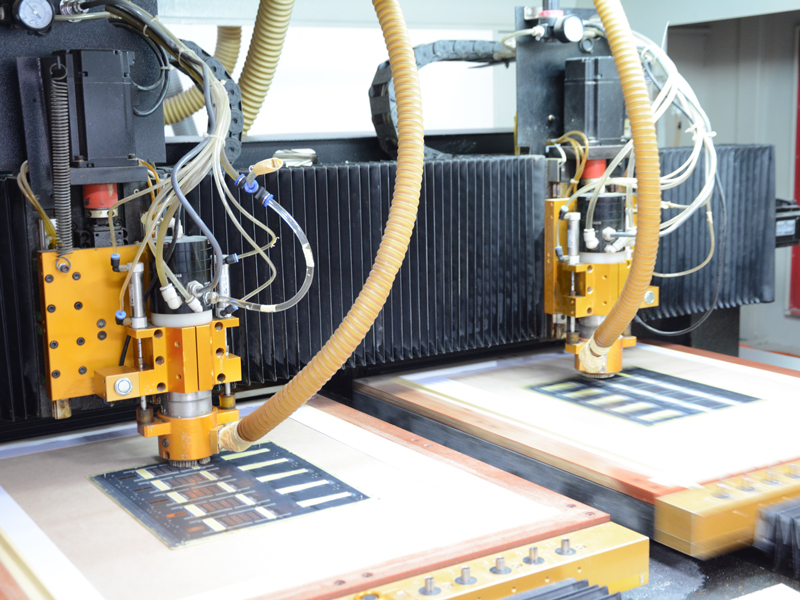

PCB produksjeproses

Shenzhen Capel Technology Co., Ltd.

PCBA Production Process

Shenzhen Capel Technology Co., Ltd.